Rapid Prototyping

In addition to our plastic injection molding operations, we also offer several prototype injection molding options. This variation of injection molding is the best fit for projects that require quick tooling at an affordable price. Both our low-pressure ren injection molding, as well as our ren vacuum form tooling offer 2-3-week lead times, while our aluminum injection molds boast a 2-5-week lead time.

Additionally, we also offer several variations of rapid prototyping, including SLS selective laser sintering which allows us to prototype parts that can withstand harsh test environments or limited volumes of end-use parts. We also offer SLA stereolithography which is most often utilized for functional parts that require high levels of resolution, accuracy, and surface finish. Depending on your project, we will work with you to determine the molding type that makes the most sense for your unique application.

Why Use Prototype Injection Molding?

If you are trying to develop a new tool, then you need to develop a prototype before you mass-produce that specific product. That is where prototype injection molding can help you. There are several reasons why this might be beneficial. These include:

- You can receive a significant amount of feedback on your individual designs. You also have the opportunity to talk with engineers who can help you address challenges during the production process.

- You can also create multiple versions of the same product, comparing the benefits and drawbacks of each option. That way, you can figure out which one works best while also reducing your overhead expenses.

- You can test the individual form and fit of the components to make sure they meet the specified task.

- You even have the opportunity to market test the product, figuring out what your customers and clients are going to like.

Clearly, there are a lot of reasons why you should invest in the prototype injection molding process.

The Prototyping Injection Molding Process

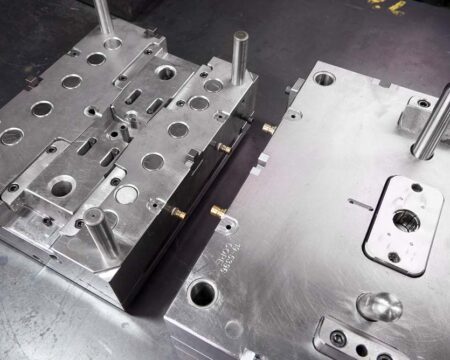

There are several steps involved in the prototyping injection molding process. First, a plastic material will be placed into a mold cavity under an extreme amount of pressure. Then, specific resins are fed into the injection molding machine. This is mixed with any coloring that is required. Over time, the coloring in resin will be heated and melted. Finally, the material will be transferred to a mold cavity where it will cool over time.

After it has cooled, the part can be removed from the cavity. Then, you can test the prototype part to see what works well and what needs to be improved. The process can be repeated until you have found the best version of the prototypes and meet your needs.

Other Types of Injection Molding

At Global Design and Development, we are proud of our prototype injection molding; however, we also offer other types of injection molding. If you are interested in other services, some of our options include:

- Plastic Injection Molds: We have the capability to produce high-quality custom plastic parts for a variety of industries. A few common examples include healthcare, cars, aerospace, defense, and even routine consumer products.

- Production Injection Molding: We also offer production injection molding. This is a versatile process that can meet a wide variety of needs. If you have a product that you need to produce quickly, you may want to use our production injection molding capabilities.

- Engineering and Design Services: If you are looking for a team that can help you develop a new product, our design and engineering process may be right for you.

- Electronic Components: If you are looking for a team that can quickly and efficiently manufacture electronic components, we can help you with this as well. We can customize our electronic components to meet your needs.

These are just a few of the many services that we offer. We have worked hard to expand our services to make sure we can meet or exceed your expectations. If you are looking for a custom job, reach out to us to learn more about how we can help you.

Global Design and Development for Prototyping Injection Molding

Clearly, there is a lot that prototype injection molding has to offer, but you also need to work with a team that has a significant amount of experience in this area. That is where we can help you. We are Global Design and Development, and we have an unparalleled level of experience when it comes to injection molding. We have the ability to customize our processes to meet your specific needs. That way, you can get the most out of your investment. We will work with you personally, figuring out how we can place your business in the best position possible to be successful. If you would like to learn more about how our injection molding options, please contact us today. We look forward to meeting you.